@3Shape: Do you love great Blogs? Valerie Biccum, from Kastle Mills speaks openly about TRIOS in her new exciting industry blog. http://bit.ly/PXye2z Shared via TweetCaster

Tuesday, September 4, 2012

Tuesday, August 21, 2012

Maxillary arch scan with the 3Shape TRIOS® Kastle Mills

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: Maxillary arch scan with the 3Shape TRIOS®: The 3Shape TRIOS® was designed to make a difference in your clinic with smooth and easy digital workflow. This next generation intraoral ...

Need a price for the Trios call us today for the cost of the Trios

Need a price for the Trios call us today for the cost of the Trios

3Shape TRIOS Cost - Order Form with Color Tool

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: 3shape TRIOS - Order Form with Color Tool: Impression taking has never been easier ... TRIOS contains a broad array of smart tools that empowers you with full control. The TRIOS by ...

3Shape Trios Cost ask us for a price quote today

3Shape Trios Cost ask us for a price quote today

Monday, August 20, 2012

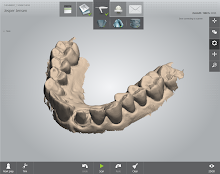

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: Scanning the Mandibular arch with 3Shape TRIOS

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: Scanning the Mandibular arch with 3Shape TRIOS: It all starts with a good impression! That is the most accurate statement I have ever heard when it comes to restorative dentistry. Obtai...

We are now taking deposits in Canada for the 3Shape Trios

We are the authorized Canadian Distributor for the 3Shape Trios

We are now taking deposits in Canada for the 3Shape Trios

We are the authorized Canadian Distributor for the 3Shape Trios

Wednesday, August 15, 2012

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: 3Shape TRIOS® New scanner represents the next gene...

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: 3Shape TRIOS® New scanner represents the next gene...: Inside Dentistry August 2012, Volume 8, Issue 8 3Shape TRIOS® New scanner represen...

3Shape TRIOS®

New scanner

represents the next generation in digital impression taking.

Moving beyond

scanning for copings and crowns alone, TRIOS is designed to easily and

efficiently deal with even complex clinical situations and quickly provides

consistent, accurate, high-quality restoration results for an extensive range of

indications.

Features and Benefits

TRIOS does not

involve spraying, which can ruin scan accuracy, is uncomfortable for patients,

and prolongs chairtime. Designed for ease of use, it can be used by both

dentists and assistants after receiving brief instructions, and does not need to

be held at a specific distance or angle for focus. Users can even rest the

scanner on the teeth for support as they scan. It combines hundreds or thousands

of 3-D pictures to create the final 3-D digital impression based on real data

rather than interpolated artificial surfaces. It is 100 times faster than

conventional video cameras, capturing more than 3,000 2-D images per second. Its

autoclaveable tip, which can be flipped for alternating between scanning upper

and lower jaws, provides optimal hygiene and meets clinical requirements. Its

live 3-D visualization and motion-sensor interface enables dentists to view the

digital impression being built on their touch screen during scanning, using the

hand-held scanner to virtually rotate and turn the 3-D digital impression for

easy viewing at all angles without touching the screen.

Tools for New Orders, Corrections, Validation

The

TRIOS® order form, which can be customized to match the laboratory’s

specific information requirements and offerings, makes it fast and easy to

create new orders, attach 2-D images, and convey all case aspects to the

laboratory. Dentists can conveniently mark detailed tooth color information

directly on an illustration of the tooth.

When initial

scanning results are not satisfactory, the TRIOS® Undo/Redo feature

lets users edit their scans, delete unwanted details, and rescan specific

regions as they build up flawless impression results.

TRIOS’s built-in

tools for instant clinical validation help to ensure the high quality of the

impression and tooth preparation while the patient is still in the chair (Figure

1). The Occlusal Clearance tool measures distance to ensure adequate space for

the particular restoration, and the Insertion Direction tool controls prepared

teeth for convergence/divergence. Rotate-and-zoom functionality lets dentists

easily validate an impression’s quality on their screen and add comments to the

laboratory directly on the 3-D image.

Laboratory Communication

The Communicate™

solution, which is optimized for sharing case information as 3-D images, offers

dentists immediate and efficient 2-way communication with their laboratory to

help them ensure optimal results. For example, laboratory technicians can verify

details in the digital impression sent from the clinic, laboratories can send

their design and margin line proposals and get back comments from the dentist,

and dentists can view and discuss with their patients the virtual diagnostic

wax-ups sent from the laboratory (Figure 2 and Figure 3).

Multiple Indications, Flexibility

TRIOS scans allow

dentists to work with the laboratory of their choice and enjoy a wide range of

dental indications, laboratory technician expertise, and a flexible choice of

materials. TRIOS supports crowns, bridges, inlays, onlays, and veneers with

subgingival preparation. TRIOS’s scan accuracy enables dentists to easily

capture single-implant positions, using validated scan-bodies, and improve final

esthetics by adding a scan of the soft-tissue emergence profile. 3Shape

laboratories receiving pre-preparation digital impressions can use their CAD

software to produce and send back cost-efficient temporaries and diagnostic

wax-ups in highly esthetic designs based on the digital impression

alone.

As TRIOS is not

tied to a specific model provider, dentists and laboratories can shop freely

among model types, manufacturing methods, and model services to match their

models to the specific patient case, while optimizing turnaround time and costs.

Laboratories using 3Shape CAD can offer support for fully functional implant

models.

Conclusion

With features

geared to a dental clinic’s internal workflows and external service needs, the

TRIOS system’s technology advancements has set new standards for

impression-taking in terms of accuracy, speed, and ease of use, providing

clinicians with new ways to see more patients and deliver consistent,

high-quality dental care.

Now taking deposits on Pre-Orders.

Contact me! Valerie at Kastle Mills Corp.

1-778-478-0359

Twitter - @KastleMills

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: Introduction

3Shape TRIOS Digital Impression System / Intraoral Scanner Blog from Kastle Mills Corp.: Introduction: Hello, My name is Valerie, I am a Certified Dental Assistant working with Kastle Mills Corp. specializing in Digital Workflow and Intraor...

Tuesday, July 10, 2012

Kastle Mills Ortho Bite Splint Milled on Roland DWX-50 with Microbur CAM Strategy

As we `drill down' into all the value adds from the Roland DWX-50 we have now delivered on a milled bite splint from a full digital workflow!

The fit from the Roland milled bite splint was well impressive! The reason for this was our proprietary microbur pak deploying a .6mm and .3mm bur.

This SUM3D Microbur milling strategy is only available from CAP in the US and Kastle Mills in Canada for the Roland DWX-50

http://screencast.com/t/sRfYMshhk8B (Video of Bite Splint)

Imagine what you can achieve with the new 3Shape Ortho Appliance Builder and the Roland DWX-50 with SUM3D Microbur pak from Kastle Mills.

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

The fit from the Roland milled bite splint was well impressive! The reason for this was our proprietary microbur pak deploying a .6mm and .3mm bur.

This SUM3D Microbur milling strategy is only available from CAP in the US and Kastle Mills in Canada for the Roland DWX-50

http://screencast.com/t/sRfYMshhk8B (Video of Bite Splint)

Imagine what you can achieve with the new 3Shape Ortho Appliance Builder and the Roland DWX-50 with SUM3D Microbur pak from Kastle Mills.

3Shape Ortho 2012 and 3Shape Appliance Builder from Kaste Mills. Ortho Roland DWX-50 Microbur kit SUM3D from Kastle Mills .6mm .3mm

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

What Dental Lab owners are saying about the Roland DWX-50

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

2nd Annual CAM/CAM Conference Dental Automation

The 2nd Annual CAM/CAM Conference will be August 2012 in Kelowna BC

The 2nd Annual CAM/CAM Conference will be August 2012 in Kelowna BCKastle Mills and CAP have spent the past year `growing dental labs' through various means:

- Business Development and Marketing

- Custom Automated Manufacturing

- Reengineering Conventional Dental Workflows to Deploy Digital Dental Automation

- Creating Automated Dental `Ecosystems' for Compact Inhouse Manufacturing of Digital Prosthetics

We had to look in the mirror an now recognize `automation is now here' at a price point that is acceptable and essential for dental labs to stay competitive.

It is important to remember a few points to enable success in this new era.

- If you purchase digital dental equipment you will likely be only as `successful' as `the level of support' you are expected to receive from that company.

- If you purchase cheap digital dental equipment you will get limited or no support, limited dental IQ and limited access to scale up your business downstream

- If you purchase digital dental equipment from a big box company or a non dental company, expect just that! dental equipment in the box with a how to manual and 1800 number Overseas.

The important piece to remember is to select the right resources, complete your diligence and purchase the right equipment. Then you will need to use `that distributor' to enable the base that will be your platform for continued success!

Core Competency and Workflow Assessment, Change Management Plan for Employees for `buy in' Site Planning for Equipment, Delivery, Onsite Installation and Training at your location with your team by certified trainers, Workflow Design Templates, Prosthetic Manufacturing Techniques, Production and Post Production Education, Execution of Final Digital Prosthetics and Continued Support. I know you are wondering - what the hell are we talking about? who does this?

This is why most `technology sales' don't get the market uptake they should - great products can be dust collectors without the proper planning and support required to enable such a workflow. However when such a workflow is enabled with this expertise and support ` a footprint' or `automation template' it offers unprecedented value and savings not to mention unmatched turnaround times for prosthetics. Below is a picture of e.max press crowns from a 3Shape design that was then manfactured in wax

[caption id="attachment_1147" align="alignleft" width="300" caption="Automated E.max Press"]

[/caption]

[/caption]It's starts at $45,000.00 with a new 3Shape Dental Scanner and Roland Mill or 3D Printer

That is the issue that milling centre's will have to face (we looked in the mirror) as the price of the right technology is now here!

Fact: you don't need to be a rocket scientist to run a mill or printer - limited dental IQ required.

Fact: you don't need a 2000kg $250k mill to create ultra precise Zi substructures and crowns, mill temps anymore - and you can create savings in almost every area of your conventional workflow with this technology - it's not just what you outsource! Is this your new wax department?

This new access to `technology' at this price point impacts us all. What should I do? What can we do? Should I buy this equipment? Is digital automation for me? If I don't act how will it impact my business?

We actually thought the same thing you might be, this is fad or the technology is not quite there - we were not accurate! It's here and through our peers in Canada and the US we know just how fast these mills and printers are moving off the shelves! The Economics work

We saw this some time ago - we tend to be quite innovative and offer what we feel is the best digital equipment available - We now help and empower dental labs with inhouse manufacturing because it's better to be steering the car then being passed by it standing on the side of the road

There is nothing a business can do but change `every business' will have to inorder to stay profitable, however it's how much you change when?

This will be the basis of our discussions this year Inhouse Manufacturing of Digital Prosthetics - Dental Automation.

Look for our RSVP coming soon

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Custom Implant Abutments - 3Shape Dental Scanners

Narrow down your choices to find the best fit patient-specific implant abutments. We thought this was a great article as Kastle Mills and CAP now offer Patient Specific 3Shape CAD/CAM Abutments for our customers as well as Atlantis Abutments. All Health Canada FDA and ISO.

By Chris Brown, BSEE

The first modern-day dental implants were placed nearly 60 years ago. Today, there are numerous options for dental implant materials, surface finishes, platform switching, engaging versus non-engaging. Technicians and clinicians now have more choices than ever when it comes to implant abutments from different materials and different coatings to off-the-shelf, pre-made abutments or custom patient-specific abutments.

Why choose custom abutments when stock abutments are so readily available with different angulations, finishes, and materials? There are many cases where stock abutments can work just fine—assuming the oral surgeon has sufficient room and sufficient bone and tissue to place the implant in an ideal position.

However, for those less-than-ideal cases, custom implant abutments are a fantastic option. They give technicians the ability to create an ideal emergence profile that promotes healthy tissue development and to place margins uniformly below the gingiva. In addition, the use of a custom abutment allows corrections to be made in angulation with anatomical structure for better support and crown retention.

Every technician knows how labor-intensive traditional crown-and-bridge fabrications can be. Each case is unique and requires individual attention from model making to waxing and casting, and to layering, staining, and glazing. Custom implant abutments are just as unique and often are even more challenging from a design perspective.

Just as CAD/CAM technology has brought efficiencies in design and manufacturing processes for crown-and-bridge fabrication, it is doing the same for custom implant abutments, so much so that many custom implant abutment solutions are now selling for less than the traditional stock abutments.

Many dental laboratories have invested in scanners and CAD software to design substructures and full-contour restorations. Individual design control, improved fit, faster turnaround time, and reduced outsourcing expenses have become proven benefits of the digital workflow. Most laboratory model scanners are sold with crown-and bridge-restorations in mind. However, laboratory owners and technicians are beginning to realize that their scanner can also enable them to provide their own custom implant abutments solutions.

All-zirconia custom abutments have become very popular. Initially only available in a bleach shade, manufacturers are now offering a variety of base shades for all-zirconia abutments. Base shading of the abutment can really make the difference when it comes to the final esthetics of the restoration. Another benefit to all-zirconia abutments is the option technicians have to use pink porcelain directly on the abutment to fill in

missing gingival tissue.

Titanium-zirconia hybrid abutments are a unique configuration. They have a titanium interface for the implant plus a cylinder to cement to a custom-milled zirconia abutment “topper,” very similar to the cast UCLA abutment concept (Figure 1). This type of abutment can provide the mechanical reliability of a titanium-to-titanium interface with the esthetic advantage of a shaded zirconia abutment. Typically, this is only an option for bone level platforms; otherwise, the titanium-zirconia margin may be visible. Extra space is also needed for this type of abutment to accommodate the titanium collar—at least a minimum thickness of 0.5 mm of zirconia and room to contour a margin for the final restoration. Laboratories and milling centers with zirconia milling capability are able to create these abutments in-house.

Some implant manufacturer representatives claim that implant warranties become null and void when a third-party abutment of compatible hardware is used. It is tough to say if this position has legal legs to stand on. It becomes even more ironic as a number of implant manufacturers are now offering custom abutments and parts that are compatible with other manufacturer’s implants.

Companies such as Dentsply Implants North America (Astra Tech), Custom Milling Center, GC Advanced Technologies, and Glidewell offer an

assortment of titanium and zirconia custom abutments compatible with many of today's common implant platforms. Apex Dental Milling, B&D Dental, and a number of other milling centers offer milled-titanium abutments and hybrid abutments.

The choice between using factory parts or third-party parts is one that should be made by the laboratory and clinicians involved with the case. Laboratories outsourcing abutments should clarify who is the supplier of the abutment parts with their outsourcing partners.

Manufacturers such as GC Advanced Technologies, CMC, and Glidewell accept cases and models directly from laboratories—scanning, designing, and milling the abutments at their facilities. Manufacturers such as Nobel Biocare and Straumann offer their own laboratory model scanners. Laboratories can scan cases, design their own custom abutments, and submit the case to Nobel Biocare or Straumann for milling of factory custom abutments.

3Shape and Dental Wings offer open-architecture scanners with optional abutment design modules. A laboratory or milling center with one of these scanners and the abutment module software can scan the model, design the abutment, and electronically send the abutment design to Biomet 3i, GC Advanced Technologies, CMC, Glidewell, or other outsource providers for milling. Biomet 3i provides factory 3i abutments. Any other implant platforms from these manufacturers are considered factory-compatible parts.

At this stage, for scan-only business models, the case could now be submitted electronically for the manufacturer to design and mill the abutment. Of course, the laboratory has the option to review the design prior to milling. Submitting the case electronically rather than shipping it saves the laboratory shipping time and cost and provides an overall faster turnaround time.

The design tools for abutments are very similar to those for crown-and-bridge. Scaling and positioning tools are used for large adjustments (Figure 4). The abutment can be stretched or moved in any direction necessary and waxing and morphing tools allow for contouring the abutment. There are also tools to adjust the position of the abutment margin and emergence

profile (Figure 5).

Chris, Brown. "Pub-idt." Dentalaegis.com. Dental Aegis, 2012. Web. 22 June 2012. <http://www.dentalaegis.com/idt/2012/06/custom-implant-abutments>.\

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

By Chris Brown, BSEE

The first modern-day dental implants were placed nearly 60 years ago. Today, there are numerous options for dental implant materials, surface finishes, platform switching, engaging versus non-engaging. Technicians and clinicians now have more choices than ever when it comes to implant abutments from different materials and different coatings to off-the-shelf, pre-made abutments or custom patient-specific abutments.

Why choose custom abutments when stock abutments are so readily available with different angulations, finishes, and materials? There are many cases where stock abutments can work just fine—assuming the oral surgeon has sufficient room and sufficient bone and tissue to place the implant in an ideal position.

However, for those less-than-ideal cases, custom implant abutments are a fantastic option. They give technicians the ability to create an ideal emergence profile that promotes healthy tissue development and to place margins uniformly below the gingiva. In addition, the use of a custom abutment allows corrections to be made in angulation with anatomical structure for better support and crown retention.

Every technician knows how labor-intensive traditional crown-and-bridge fabrications can be. Each case is unique and requires individual attention from model making to waxing and casting, and to layering, staining, and glazing. Custom implant abutments are just as unique and often are even more challenging from a design perspective.

Just as CAD/CAM technology has brought efficiencies in design and manufacturing processes for crown-and-bridge fabrication, it is doing the same for custom implant abutments, so much so that many custom implant abutment solutions are now selling for less than the traditional stock abutments.

Many dental laboratories have invested in scanners and CAD software to design substructures and full-contour restorations. Individual design control, improved fit, faster turnaround time, and reduced outsourcing expenses have become proven benefits of the digital workflow. Most laboratory model scanners are sold with crown-and bridge-restorations in mind. However, laboratory owners and technicians are beginning to realize that their scanner can also enable them to provide their own custom implant abutments solutions.

Abutment Materials

CAD/CAM-based custom abutments are available in three material configurations: all-titanium, all-zirconia, and titanium-zirconia hybrids. Given its strength, ease of milling, and lower cost, all-titanium is a very common choice. Additionally, some manufacturers offer optional special coatings such as gold nitride to enhance the esthetics of the final restoration.All-zirconia custom abutments have become very popular. Initially only available in a bleach shade, manufacturers are now offering a variety of base shades for all-zirconia abutments. Base shading of the abutment can really make the difference when it comes to the final esthetics of the restoration. Another benefit to all-zirconia abutments is the option technicians have to use pink porcelain directly on the abutment to fill in

missing gingival tissue.

Titanium-zirconia hybrid abutments are a unique configuration. They have a titanium interface for the implant plus a cylinder to cement to a custom-milled zirconia abutment “topper,” very similar to the cast UCLA abutment concept (Figure 1). This type of abutment can provide the mechanical reliability of a titanium-to-titanium interface with the esthetic advantage of a shaded zirconia abutment. Typically, this is only an option for bone level platforms; otherwise, the titanium-zirconia margin may be visible. Extra space is also needed for this type of abutment to accommodate the titanium collar—at least a minimum thickness of 0.5 mm of zirconia and room to contour a margin for the final restoration. Laboratories and milling centers with zirconia milling capability are able to create these abutments in-house.

Factory vs. Factory-Compatible - A Must Read

Every implant manufacturer would prefer to be the sole supplier of stock and custom implant abutments. For years, laboratories have been modifying stock abutments, and casting their own UCLA abutments, usually with parts from the implant company. Today, a number of third-party companies offer stock abutments and parts compatible with the factory implants.Some implant manufacturer representatives claim that implant warranties become null and void when a third-party abutment of compatible hardware is used. It is tough to say if this position has legal legs to stand on. It becomes even more ironic as a number of implant manufacturers are now offering custom abutments and parts that are compatible with other manufacturer’s implants.

Companies such as Dentsply Implants North America (Astra Tech), Custom Milling Center, GC Advanced Technologies, and Glidewell offer an

assortment of titanium and zirconia custom abutments compatible with many of today's common implant platforms. Apex Dental Milling, B&D Dental, and a number of other milling centers offer milled-titanium abutments and hybrid abutments.

The choice between using factory parts or third-party parts is one that should be made by the laboratory and clinicians involved with the case. Laboratories outsourcing abutments should clarify who is the supplier of the abutment parts with their outsourcing partners.

Scan/Design Options

Straumann and Biomet 3i now have digital impression integrations that allow the dentist to scan the patient’s mouth using the Lava™ C.O.S. (3M ESPE, www.3mespe.com) or an iTero™ (Align Technology, Inc., www.aligntech.com) and directly send the case to the laboratory. For other cases from traditional impressions, the laboratory must still pour the model and the cases must be scanned with a model scanner.Manufacturers such as GC Advanced Technologies, CMC, and Glidewell accept cases and models directly from laboratories—scanning, designing, and milling the abutments at their facilities. Manufacturers such as Nobel Biocare and Straumann offer their own laboratory model scanners. Laboratories can scan cases, design their own custom abutments, and submit the case to Nobel Biocare or Straumann for milling of factory custom abutments.

3Shape and Dental Wings offer open-architecture scanners with optional abutment design modules. A laboratory or milling center with one of these scanners and the abutment module software can scan the model, design the abutment, and electronically send the abutment design to Biomet 3i, GC Advanced Technologies, CMC, Glidewell, or other outsource providers for milling. Biomet 3i provides factory 3i abutments. Any other implant platforms from these manufacturers are considered factory-compatible parts.

Model Scanning

Typical laboratory workflow is conceptually the same even though scanners and CAD software may vary among manufacturers. The challenge in scanning custom abutment cases is accurately identifying the position of the implant. Even though today’s scanners are very accurate, they have difficulty scanning the area inside of the analog on the model to properly gauge depth, position, and angulation. The solution is to place a scan locator or scan abutment in the model analog and then scan the model. Figure 2 shows a scan locator for a Zimmer implant abutment in tooth position No. 30. The CAD software will use the flat surface on the scan locator to calculate the location and orientation of the analog in the model. Figure 3 shows a scan locator for a Nobel Replace abutment in the place of tooth No. 9 within the abutment design module of a popular CAD software program.At this stage, for scan-only business models, the case could now be submitted electronically for the manufacturer to design and mill the abutment. Of course, the laboratory has the option to review the design prior to milling. Submitting the case electronically rather than shipping it saves the laboratory shipping time and cost and provides an overall faster turnaround time.

Abutment Design

Abutment design modules are available for the most common dental CAD software packages. They often come with an additional upfront cost and annual maintenance fees, unless the scanner is supplied by an implant manufacturing company.The design tools for abutments are very similar to those for crown-and-bridge. Scaling and positioning tools are used for large adjustments (Figure 4). The abutment can be stretched or moved in any direction necessary and waxing and morphing tools allow for contouring the abutment. There are also tools to adjust the position of the abutment margin and emergence

profile (Figure 5).

Additional Benefits

Most laboratory CAD programs support concurrent design of the custom abutment and the substructure or full-contour restoration. The benefits are three-fold. This allows for concurrent manufacturing of the abutment and coping/full-contour restoration, speeding up case processing time. It also allows the designer to take into account the shape and position of the final restoration during the design of the abutment. Finally, it bypasses the need to re-scan the case for the coping/full-contour restoration design, as scanning abutments can be time-consuming and very technique sensitive.Conclusion

Custom abutments give technicians more control over esthetics and support. They give technicians yet another opportunity to design and build cases for success from the beginning. Watch for more dental CAD programs to offer custom abutment module integrations with both factory and factory-compatible implant manufacturers. Custom implant abutments are already a growing market segment for most dental laboratories. It is a trend that does not show any signs of slowing.About the Author

Chris Brown is the manager of Apex Dental Milling in Ann Arbor, Michigan.Chris, Brown. "Pub-idt." Dentalaegis.com. Dental Aegis, 2012. Web. 22 June 2012. <http://www.dentalaegis.com/idt/2012/06/custom-implant-abutments>.\

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Lingual orthodontics - The future is lingual?

In the first in a series of articles from British Lingual Ortodontic Society, Rob Slater on why lingual orthodontics is establishing itself as a technique for the 21st century

Lingual orthodontics - braces worn behind the teeth - has been practised in the UK for at least 30 years now, but it is only in the last 10 years that demand for the technique has escalated. Among those requesting the lingual technique are patients who refused to consider orthodontics in the past because of the appearance of fixed appliances.

Members of the British Lingual Orthodontic Society (BLOS) are enjoying high demand from adult patients who want straight teeth without Ugly Betty train tracks. The lingual technique is a system described by some orthodontic specialists as “One of the most important dental developments of the 21st century.”

As a specialty, orthodontics is the oldest and has enjoyed enormous innovation and a wide variety of systems, broadly featuring: Edgewise at the start of the 20th century, Begg in the 1920s, straightwire in the 1970s, aligner systems in the 1990s and now lingual today. However, it is still not taught in any of the dental schools and remains a technique that specialists must learn for themselves.

Interestingly, lingual was also around in the 1980s and 1990s, developed simultaneously in the USA and Japan. Hollywood orthodontist Dr Craven Kurz, was one of two people credited with pioneering the system. The other was Professor Kinya Fujita, who invented lingual braces in Japan for martial arts combatants who wanted to avoid the risk of mucosal lacerations from labial appliances.

In the UK, however, a generation of orthodontic specialists tried out lingual orthodontics but largely gave up early on. It’s agreed that not enough research was carried out beforehand and the mechanical challenges were too great for the technique to be more widely accepted. All this has changed, however, and now lingual orthodontics is in vogue.

As a result of important research (1) published last year, lingual practitioners can be satisfied that there is a lower risk of visible marking or decay on the teeth among patients whose oral hygiene is poor.

The research compared braces on the outside surfaces of the teeth with those on the inside (lingual) surface and showed:

• The outer surface of the teeth are more prone to white spot lesions (WSL)

• The number of WSL that appeared was nearly five times greater when the braces were placed on the outer surface than when they were on the inside surface.

• When WSL did develop, it was 10.6 times more extensive when the braces were on the outer surface than when they were on the inside surface

If visible WSL did develop, it was behind the teeth and therefore invisible if lingual braces were used.

The increase in demand for this style of treatment has necessitated a change in the training pathways for orthodontic specialists and a change in the dissemination of information about this complex subject to the public

The British Lingual Orthodontic Society (BLOS) is the UK’s only society dealing exclusively with lingual orthodontics and is affiliated to the British Orthodontic Society. The aim of the society since its inception in 1995was:

· To provide an organized community for orthodontic specialists who practice lingual orthodontics

· To represent lingual orthodontics and orthodontists in the UK

· To promote excellence in this field by continuing to raise standards

· To provide a source of evidence supported information for the general public to allow them to make the right choices about their treatment

· To provide a way to find a lingual orthodontist in your area

The society has changed and grown with the needs of its members and the public to reflect the dramatic increase in the demand for invisible treatment for adults and children.

At the core of the society is the committee of ten experienced lingual orthodontists who meet four times per year to manage the running of the society. Within this structure, there are various sub-groups who coordinate the current projects.

One of the biggest developments has been the introduction of a two-tier membership enabling BLOS members to achieve accreditation. The format involves submission of three orthodontic cases treated with lingual appliances on all teeth involving extraction and non-extraction based treatment plans with the aim of demonstrating clinical excellence.

Cases are assessed against a standard and established set of criteria by an experienced panel of judges. Only those candidates who achieve the highest standards will become BLOS accredited.

Reference

van der Veen MH, Attin R, Schwestka-Polly R, Wiechmann D. Caries outcomes after orthodontic treatment with fixed appliances: do lingual brackets make a difference? Eur J Oral Sci 2010; 118: 298–303

Robert Slater has an orthodontic practice in Birmingham and is an Associate Clinical Teaching Fellow at Warwick University where he teaches on the Masters Programme in Lingual Orthodontics and is also an examiner on the Orthodontic Therapists Programme. He is a founding member of the British Lingual Orthodontic Society (BLOS) and, the immediate past Chairman.

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Lingual orthodontics - braces worn behind the teeth - has been practised in the UK for at least 30 years now, but it is only in the last 10 years that demand for the technique has escalated. Among those requesting the lingual technique are patients who refused to consider orthodontics in the past because of the appearance of fixed appliances.

Members of the British Lingual Orthodontic Society (BLOS) are enjoying high demand from adult patients who want straight teeth without Ugly Betty train tracks. The lingual technique is a system described by some orthodontic specialists as “One of the most important dental developments of the 21st century.”

As a specialty, orthodontics is the oldest and has enjoyed enormous innovation and a wide variety of systems, broadly featuring: Edgewise at the start of the 20th century, Begg in the 1920s, straightwire in the 1970s, aligner systems in the 1990s and now lingual today. However, it is still not taught in any of the dental schools and remains a technique that specialists must learn for themselves.

Interestingly, lingual was also around in the 1980s and 1990s, developed simultaneously in the USA and Japan. Hollywood orthodontist Dr Craven Kurz, was one of two people credited with pioneering the system. The other was Professor Kinya Fujita, who invented lingual braces in Japan for martial arts combatants who wanted to avoid the risk of mucosal lacerations from labial appliances.

In the UK, however, a generation of orthodontic specialists tried out lingual orthodontics but largely gave up early on. It’s agreed that not enough research was carried out beforehand and the mechanical challenges were too great for the technique to be more widely accepted. All this has changed, however, and now lingual orthodontics is in vogue.

As a result of important research (1) published last year, lingual practitioners can be satisfied that there is a lower risk of visible marking or decay on the teeth among patients whose oral hygiene is poor.

The research compared braces on the outside surfaces of the teeth with those on the inside (lingual) surface and showed:

• The outer surface of the teeth are more prone to white spot lesions (WSL)

• The number of WSL that appeared was nearly five times greater when the braces were placed on the outer surface than when they were on the inside surface.

• When WSL did develop, it was 10.6 times more extensive when the braces were on the outer surface than when they were on the inside surface

If visible WSL did develop, it was behind the teeth and therefore invisible if lingual braces were used.

The increase in demand for this style of treatment has necessitated a change in the training pathways for orthodontic specialists and a change in the dissemination of information about this complex subject to the public

The British Lingual Orthodontic Society (BLOS) is the UK’s only society dealing exclusively with lingual orthodontics and is affiliated to the British Orthodontic Society. The aim of the society since its inception in 1995was:

· To provide an organized community for orthodontic specialists who practice lingual orthodontics

· To represent lingual orthodontics and orthodontists in the UK

· To promote excellence in this field by continuing to raise standards

· To provide a source of evidence supported information for the general public to allow them to make the right choices about their treatment

· To provide a way to find a lingual orthodontist in your area

The society has changed and grown with the needs of its members and the public to reflect the dramatic increase in the demand for invisible treatment for adults and children.

At the core of the society is the committee of ten experienced lingual orthodontists who meet four times per year to manage the running of the society. Within this structure, there are various sub-groups who coordinate the current projects.

One of the biggest developments has been the introduction of a two-tier membership enabling BLOS members to achieve accreditation. The format involves submission of three orthodontic cases treated with lingual appliances on all teeth involving extraction and non-extraction based treatment plans with the aim of demonstrating clinical excellence.

Cases are assessed against a standard and established set of criteria by an experienced panel of judges. Only those candidates who achieve the highest standards will become BLOS accredited.

Reference

van der Veen MH, Attin R, Schwestka-Polly R, Wiechmann D. Caries outcomes after orthodontic treatment with fixed appliances: do lingual brackets make a difference? Eur J Oral Sci 2010; 118: 298–303

Robert Slater has an orthodontic practice in Birmingham and is an Associate Clinical Teaching Fellow at Warwick University where he teaches on the Masters Programme in Lingual Orthodontics and is also an examiner on the Orthodontic Therapists Programme. He is a founding member of the British Lingual Orthodontic Society (BLOS) and, the immediate past Chairman.

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Dental Marketing 101: Using Your Newsletter (Dental Labs or Dentists)

Dental Marketing 101: Using Your Newsletter

Most dentists that were spoken to have spoken to have tried sending out a newsletter, either electronic or paper, at some point in the past. However, few of them have been completely satisfied with their response. The truth is that running a successful newsletter campaign takes careful planning. To maximize the value you receive from your newsletter, keep these four principles in mind:

1) Publish on a regular basis. A monthly newsletter is great, but many practices determine that this is too much of a commitment. If that’s the case, make sure you commit to a specific schedule—bi-monthly or quarterly, for instance. Repetition and consistency is key, and if your publishing schedule is erratic, your audience will have no idea what to expect.

2) Provide valuable content. If you expect your audience to read your newsletter, it’s important that you provide value. This can include valuable tips for better oral health, a discussion of recent news that impacts your patients, or anything else that adds value to the lives of your readers. The bottom line is this: if you can’t provide a good reason for your recipients to read your newsletter, they won’t.

3) Make it personal. A primary goal of regular newsletter publishing is to build a relationship with your patients. Your newsletter is a great opportunity to let them get to know you personally—whether it is sharing pictures of your family or writing about your favorite sports team. Strong relationships lead to long-term loyalty—and letting your patients get to know you is a great way to build strong relationships!

4) Offer promotions and special deals. Finally, your newsletter is a great place to advertise special deals. Everyone loves to save money, and by including valuable coupons or special offers, you can ensure that much of your audience looks forward to your newsletter arriving in the mail! Your newsletter is also a great place to promote services that are currently being underutilized.

Your newsletter can be a powerful marketing tool for your dental practiceor dental lab —but it won’t happen automatically. A successful newsletter requires planning and commitment… but if you’re willing to put in the time, your newsletter can be one more arrow in your marketing quiver.

Special thanks to David Schwab

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Kastle Mills 3Shape Design for SNAP to Wax up 6unit Bridge

Do you require advanced CAD design training for your 3Shape dental scanner? Well Kastle Mills can help!

Contact Us to arrange for additional training from our 3Shape Certified Trainers (R.D.T) at Kastle Mills.

We welcome all customers even if you did not purchase your 3Shape dental scanner from Kastle Mills.

We come to your location, complete an assessment on your core competency and exisiting workflow. An optimized 3Shape training program is then created and deployed for your team to provide the ROI you are looking for. From Basic 3Shape CAD training and automation to Advanced digital workflows for 3Shape Elite CAD Design customers.

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Kastle Mills 3Shape 2012 Smile Composer is Launched

Kastle Mills 3Shape 2012 Smile Composer is updated for 3shape D500 3Shape D700 3Shape D800

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

New Advanced 3Shape Design Video's from Kastle Mills (Lee Cain)

http://www.youtube.com/watch?v=Yo4DlhV_RBQ&feature=relmfu

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Kastle Mills is offering Roland DWX-50 dental mills in Canada

Kastle Mills is offering Roland DWX-50 dental mills in Canada - Why Would you buy a mill from a non dental company?

With such an important purchase - as milling experts and strictly dental only - Kastle Mills w/CAP have stepped up to make this easy! no fragmentation just a turn key solution from start to finish for our customers.

DWX Dental Milling Machines are Roland’s newest CNC milling devices built on more than 20 years of experience. The result is a compact design, clean, quiet operation, and precision machining of copings, crowns and bridges.

The all new DWX-50 streamlines the production process with 5-axis simultaneous machining capability and a 5-station automatic tool changer. With our strategic partner CAP we have integrated a proprietary CAM strategy that uses a 0.3 mm tool. This provides incredibly robust and detailed anatomy. An integrated air blower system provides quick cleanup of difficult to machine materials, such as PMMA or zirconia, along with a built-in dust collection tray that can be easily connected to any lab vacuum system, keeping the cutting area clean and free of debris.

While there are numerous dental milling machines in the marketplace, only the DWX Series delivers the advanced features the market demands at an attractive price point – backed by Roland’s proven reliability and legendary support.

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

With such an important purchase - as milling experts and strictly dental only - Kastle Mills w/CAP have stepped up to make this easy! no fragmentation just a turn key solution from start to finish for our customers.

DWX Dental Milling Machines are Roland’s newest CNC milling devices built on more than 20 years of experience. The result is a compact design, clean, quiet operation, and precision machining of copings, crowns and bridges.

The all new DWX-50 streamlines the production process with 5-axis simultaneous machining capability and a 5-station automatic tool changer. With our strategic partner CAP we have integrated a proprietary CAM strategy that uses a 0.3 mm tool. This provides incredibly robust and detailed anatomy. An integrated air blower system provides quick cleanup of difficult to machine materials, such as PMMA or zirconia, along with a built-in dust collection tray that can be easily connected to any lab vacuum system, keeping the cutting area clean and free of debris.

While there are numerous dental milling machines in the marketplace, only the DWX Series delivers the advanced features the market demands at an attractive price point – backed by Roland’s proven reliability and legendary support.

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

The two-step method is the more effective alternative for implant placement - the debate

Periodontists routinely grow bone in the mouth to guarantee a stable environment for teeth and tooth implants. But whether it's better to build up bone before placing the implant, or to simply place the implant and allow bone to grow around it, has been a subject of considerable medical debate.

Now Prof. Zvi Artzi of Tel Aviv University's Maurice and Gabriela Goldschleger School of Dentistry at the Sackler Faculty of Medicine has completed a study that concludes the two-step method is the more effective alternative - building bone first, then implanting and allowing further bone growth. Currently, many dental professionals prefer a one-step process to save their patients from an additional surgical procedure.

Published in the Journal of Clinical Periodontology, Prof. Artzi's study shows that a one-step implant will show more wear and tear over time than one implanted through the more cautious two-step procedure. While both are clinically effective methods, he concludes, implant placement procedures done with the one-step method show greater bone resorption around the implant neck - a process by which the bone is broken down. Bonding of the bone around the implant was also shown to be inferior.

Proven procedures

The successful placement of a tooth implant is based on the biocompatibility of titanium, the main component of most dental and orthopedic implants. Both animal and human tissues readily accept the implant and grow around it. But in many cases, the amount of bone is also crucial to the success of the implant. Building bone to stabilize a titanium fixture is a long-standing procedure in dentistry.

Periodontists typically choose either the one-step or two-step procedure based on their preference alone. So Prof. Artzi and his fellow researchers set out to determine which procedure was scientifically superior in the long-term, well past the time when periodontists would typically monitor a patient's progress. In their study, they compared both methods of implantation in lab animals, and followed the progress of the implants over a course of two years.

The one-step procedure is based on the idea that a bone graft will simply attract the surrounding tissue to build up bone around the titanium implant - a process called conduction. The benefit of this procedure is that patients are only subjected to one surgery. But the study shows a difference in long-term efficacy, Prof. Artzi says. Ultimately, the bone recedes less in the more cautious two-step procedure. The quality of the resulting bone itself is similar.

A judgement call

Though the study proves that the two-step method is more advantageous in most cases, each case is different, says Prof. Artzi. For example, dental professionals also take into account the already existing bone - which determines how stable a future implant will be - before deciding which route to take with each individual patient. Clinically, both methods remain sound, and periodontists should still rely on their own judgement as to what is best for the patient.

Special Thanks to Journal of Clinical Periodontology

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Now Prof. Zvi Artzi of Tel Aviv University's Maurice and Gabriela Goldschleger School of Dentistry at the Sackler Faculty of Medicine has completed a study that concludes the two-step method is the more effective alternative - building bone first, then implanting and allowing further bone growth. Currently, many dental professionals prefer a one-step process to save their patients from an additional surgical procedure.

Published in the Journal of Clinical Periodontology, Prof. Artzi's study shows that a one-step implant will show more wear and tear over time than one implanted through the more cautious two-step procedure. While both are clinically effective methods, he concludes, implant placement procedures done with the one-step method show greater bone resorption around the implant neck - a process by which the bone is broken down. Bonding of the bone around the implant was also shown to be inferior.

Proven procedures

The successful placement of a tooth implant is based on the biocompatibility of titanium, the main component of most dental and orthopedic implants. Both animal and human tissues readily accept the implant and grow around it. But in many cases, the amount of bone is also crucial to the success of the implant. Building bone to stabilize a titanium fixture is a long-standing procedure in dentistry.

Periodontists typically choose either the one-step or two-step procedure based on their preference alone. So Prof. Artzi and his fellow researchers set out to determine which procedure was scientifically superior in the long-term, well past the time when periodontists would typically monitor a patient's progress. In their study, they compared both methods of implantation in lab animals, and followed the progress of the implants over a course of two years.

The one-step procedure is based on the idea that a bone graft will simply attract the surrounding tissue to build up bone around the titanium implant - a process called conduction. The benefit of this procedure is that patients are only subjected to one surgery. But the study shows a difference in long-term efficacy, Prof. Artzi says. Ultimately, the bone recedes less in the more cautious two-step procedure. The quality of the resulting bone itself is similar.

A judgement call

Though the study proves that the two-step method is more advantageous in most cases, each case is different, says Prof. Artzi. For example, dental professionals also take into account the already existing bone - which determines how stable a future implant will be - before deciding which route to take with each individual patient. Clinically, both methods remain sound, and periodontists should still rely on their own judgement as to what is best for the patient.

Special Thanks to Journal of Clinical Periodontology

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

New initiatives from 3Shape A/S and Kastle Mills in Canada!

We are very excited to announce the following new initiatives from 3Shape and Kastle Mills in Canada!

- New FedEx Real Time Tracking from our manufacturing portal - just click to track it's the first of its kind in Canada!

- New lower prices for Essential Zi Copings $39.99 a unit 48hrs or less in your hands across Canada Free Shipping!

- New 3Shape Abutment Library is now available - Only from Kastle Mills and CAP for your Open Scanner! (most platforms) ISO, Health Canada Approved

- Kastle Mills is now the distributor in Canada for EnvisionTEC 3D printers - Real Solutions and automated workflows for Canada's Dental Lab Owners - Just Plug into 3Shape

- Kastle Mills is now Canada's Roland DWX -50 Mill Distributor for Dental Labs. We are Canada's only dental distributor `specializing' in just dental appilcations for Roland.

- Kastle Mills is now Canada's only 3Shape Ortho enabled reseller - further empowering existing 3Shape owners in Canada.

2. Kastle Mills is offering Essential Zi indications at $39.99 a unit less than 48hours in your hands Free Shipping and 5:00pm EST 2:00pm PST cut off's (5year warranty)

3. Kastle Mills has now deployed in conjunction with CAP our new 3Shape Abutment Library, ISO and Health Canada Approved it's brings unparalleled productivity to your abutment workflow. Access Patient Specific Abutments for the price of stock abutments (or less). German Engineered for your 3Shape Scanner further developed by CAP engineers, now ready for your 3Shape Scanner, the new Roland desktop mills from Kastle Mills and the new Kastle Mills EnvisionTEC micro printer - Abutments and Screw Retained Substructures.

4. Kastle Mills is now the Authorized Distributor in Canada for EnvisioTEC 3D Printers - Why? When you are developing automated workflowsfor e.max press and castablesyou need absolute accuracy, speed and accessibility (price) for any dental size dental lab. Very High Quality of Parts -The resolution of fine detail is unmatched by any other Rapid Prototyping system, regardless of price. The dynamic voxel thickness for each wax resin crown can be as low as 15?m. Starting from $18,000.00 The desktop Micro is coming from Kastle Mills! It's Easy It's Fast and it will dramatically reduce your labour costs! is this your new waxing department? Out of the box and ready to build dental indications in less than 10 minutes. Easy to change materials, it only takes a few minutes. Straightforward to use – simple to maintain. Predictable build times. Easy-to-install and requires only simple facilities, less than 0.3 m²floorspace!

5. The all new Kastle Mills Roland DWX-50 streamlines the production process with 5-axis simultaneous machining capability and a 5-station automatic tool changer. With our strategic partner CAP we have integrated our own proprietary (2 step) CAM strategy that uses a 0.3 mm tool. This provides incredibly robust and detailed anatomy. An integrated air blower system provides quick cleanup of difficult to machine materials, such as PMMA or zirconia, along with a built-in dust collection tray that can be easily connected to any lab vacuum system, keeping the cutting area clean and free of debris. We are the only dental only company in Canada to offer the Roland desktop mill. We offer turnkey complete systems from 3Shape to DWX-50 to CAM to Consumables! We come to you for complete set up and training! We offer multiple mills and various manufacturer cam strategies - not every dental lab should mill! but the dental labs that should we have the right solution to empower you!

6. Kastle Mills is now launching the next generation of 3Shape Ortho for D700 and D800 dental scanners. Kastle Mills Konnect our new technology (IT) arm for 3Shape is offering 3rd party integration for Dolphin Orthodontic Software. This combined with the new 3Shape Appliance Builder from 3Shape will leverage a whole new offering for full service dental labs in Canada!

As we continue to drive `open' digital dental solutions in Canada we strive towards innovation and pushing automation to better enable and empower dental lab owners in Canada.

Please see the pictures of a now fully printed denture - 3Shape 2013 Denture Design, including the Gingiva Creation tool, transforms a widespread and technique- demanding dental indication into a fast and easy digital workflow. This is just the start of innovative products to come - stay tuned!

Also Please Check out our 3Shape Video Youtube Site - See all the new 3Shape designs from Lee Cain RDT and Kastle Mills 3Shape certified 3Shape educator. http://www.youtube.com/user/kastlemills?feature=mhsn and our newest 3Shape video design by Lee 3Shape Occusal Stop http://www.youtube.com/watch?v=Yo4DlhV_RBQ&feature=plcp

Contact Us:

Address:

200-1353 Ellis Street

Kelowna, British Columbia V1Y 1Z9

Phone:

(250) 712-1344

Toll Free:

(877) 527-8535

Email:

info@kastlemills.com

Friday, June 1, 2012

Only Kastle Mills deploy's 5 tiers of 3Shape Dental Scanner support for you!

There is no `Dip and Ship’ from major chain resellers for 3Shape Dental Scanners

Only Kastle Mills and CAP deploy 5 tiers of 3Shape support for you!

1.3Shape `intuitive’ menu in (French and English)

2.CAP Academy `exclusive’ training video support site

3.Kastle Mills Support Centre (Fr/Eng/Ger/It) `Live’ online design support

4.3Shape Support Centre in NJ

5.3Shape Support Centre in Copenhagen

We also have Canada’s wide range of sales and support specialists! With a specialist in your area!

Kastle Mills will connect and plug in 3Shape digital work flows that will set your businesses apart with measurable returns! Guaranteed!

Professional support is essential `key’ to the growth and success of any new digital technology purchase! Let Kastle Mills provide you a digital work flow analysis before you purchase your next technology! We are a team of dental experts, technology trainers, engineers, programmers and customer service representatives that offer a fresh innovative 360° approach to Digital Dentistry. Canada’s Authorized 3Shape disrtibutor and certified sales and repair centre. Now offering 2012 3Shape Ortho software!

Contact us

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

Roland DWX-50 compact 5axis dental mill with SUM3D Canada 3Shape Dental Scanner

EnvisionTEC Micro Printer from $18,000 for dental wax printing only in Canada – Only from Kastle Mills

Only Kastle Mills and CAP deploy 5 tiers of 3Shape support for you!

1.3Shape `intuitive’ menu in (French and English)

2.CAP Academy `exclusive’ training video support site

3.Kastle Mills Support Centre (Fr/Eng/Ger/It) `Live’ online design support

4.3Shape Support Centre in NJ

5.3Shape Support Centre in Copenhagen

We also have Canada’s wide range of sales and support specialists! With a specialist in your area!

Kastle Mills will connect and plug in 3Shape digital work flows that will set your businesses apart with measurable returns! Guaranteed!

Professional support is essential `key’ to the growth and success of any new digital technology purchase! Let Kastle Mills provide you a digital work flow analysis before you purchase your next technology! We are a team of dental experts, technology trainers, engineers, programmers and customer service representatives that offer a fresh innovative 360° approach to Digital Dentistry. Canada’s Authorized 3Shape disrtibutor and certified sales and repair centre. Now offering 2012 3Shape Ortho software!

Contact us

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

Roland DWX-50 compact 5axis dental mill with SUM3D Canada 3Shape Dental Scanner

EnvisionTEC Micro Printer from $18,000 for dental wax printing only in Canada – Only from Kastle Mills

Nano Fillings That Kill Bacteria and Re-Mineralize the Tooth

ScienceDaily (May 1, 2012) — Scientists using nanotechology at the University of Maryland School of Dentistry have created the first cavity-filling composite that kills harmful bacteria and regenerates tooth structure lost to bacterial decay.

Rather than just limiting decay with conventional fillings, the new composite is a revolutionary dental weapon to control harmful bacteria, which co-exist in the natural colony of microorganisms in the mouth, says professor Huakun (Hockin) Xu, PhD, MS.

“Tooth decay means that the mineral content in the tooth has been dissolved by the organic acids secreted by bacteria residing in biofilms or plaques on the tooth surface. These organisms convert carbohydrates to acids that decrease the minerals in the tooth structure,” says Xu, director of the Division of Biomaterials and Tissue Engineering in the School’s Department of Endodontics, Prosthodontics and Operative Dentistry.

After a dentist drills out a decayed tooth, the cavity still contains residual bacteria. Xu says it is not possible for a dentist to remove all the damaged tissue, so it’s important to neutralize the harmful effects of the bacteria, which is just what the new nanocomposites are able to do.

The researchers also have built antibacterial agents into primer used first by dentists to prepare a drilled-out cavity and into adhesives that dentists spread into the cavity to make a filling stick tight to the tissue of the tooth. “The reason we want to get the antibacterial agents also into primers and adhesives is that these are the first things that cover the internal surfaces of the tooth cavity and flow into tiny dental tubules inside the tooth,” says Xu. The main reason for failures in tooth restorations, says Xu, is secondary caries or decay at the restoration margins. Applying the new primer and adhesive will kill the residual bacteria, he says.

Fillings made from the School of Dentistry’s new nanocomposite, with antibacterial primer and antibacterial adhesive, should last longer than the typical five to 10 years, though the scientists have not thoroughly tested longevity. Xu says a key component of the new nanocomposite and nano-structured adhesive is calcium phosphate nanoparticles that regenerate tooth minerals. The antibacterial component has a base of quaternary ammonium and silver nanoparticles along with a high pH. The alkaline pH limits acid production by tooth bacteria.

“The bottom line is we are continuing to improve these materials and making them stronger in their antibacterial and remineralizing capacities as well as increasing their longevity,” Xu says.

The new products have been laboratory tested using biofilms from saliva of volunteers. The Xu team is planning to next test its products in animal teeth and in human volunteers in collaboration with the Federal University of Ceara in Brazil.

The University of Maryland has patents pending on the nanocomposite and the primer and adhesive technologies, according to Nancy Cowger, PhD, licensing officer with the University’s Office of Technology Transfer (OTT).

At Kastle Mills we distribute, promote and drive digital dentistry in Canada with today’s leading technology and software solutions. An education hub for dentists and dental labs, we empower owners with advanced education for digital workflow, change management consulting and digital impression taking devices for increased productivity and revenue.

Contact us

3Shape Trios Scanner, Itero Intraoral Scanner

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

Rather than just limiting decay with conventional fillings, the new composite is a revolutionary dental weapon to control harmful bacteria, which co-exist in the natural colony of microorganisms in the mouth, says professor Huakun (Hockin) Xu, PhD, MS.

“Tooth decay means that the mineral content in the tooth has been dissolved by the organic acids secreted by bacteria residing in biofilms or plaques on the tooth surface. These organisms convert carbohydrates to acids that decrease the minerals in the tooth structure,” says Xu, director of the Division of Biomaterials and Tissue Engineering in the School’s Department of Endodontics, Prosthodontics and Operative Dentistry.

After a dentist drills out a decayed tooth, the cavity still contains residual bacteria. Xu says it is not possible for a dentist to remove all the damaged tissue, so it’s important to neutralize the harmful effects of the bacteria, which is just what the new nanocomposites are able to do.

The researchers also have built antibacterial agents into primer used first by dentists to prepare a drilled-out cavity and into adhesives that dentists spread into the cavity to make a filling stick tight to the tissue of the tooth. “The reason we want to get the antibacterial agents also into primers and adhesives is that these are the first things that cover the internal surfaces of the tooth cavity and flow into tiny dental tubules inside the tooth,” says Xu. The main reason for failures in tooth restorations, says Xu, is secondary caries or decay at the restoration margins. Applying the new primer and adhesive will kill the residual bacteria, he says.

Fillings made from the School of Dentistry’s new nanocomposite, with antibacterial primer and antibacterial adhesive, should last longer than the typical five to 10 years, though the scientists have not thoroughly tested longevity. Xu says a key component of the new nanocomposite and nano-structured adhesive is calcium phosphate nanoparticles that regenerate tooth minerals. The antibacterial component has a base of quaternary ammonium and silver nanoparticles along with a high pH. The alkaline pH limits acid production by tooth bacteria.

“The bottom line is we are continuing to improve these materials and making them stronger in their antibacterial and remineralizing capacities as well as increasing their longevity,” Xu says.

The new products have been laboratory tested using biofilms from saliva of volunteers. The Xu team is planning to next test its products in animal teeth and in human volunteers in collaboration with the Federal University of Ceara in Brazil.

The University of Maryland has patents pending on the nanocomposite and the primer and adhesive technologies, according to Nancy Cowger, PhD, licensing officer with the University’s Office of Technology Transfer (OTT).

At Kastle Mills we distribute, promote and drive digital dentistry in Canada with today’s leading technology and software solutions. An education hub for dentists and dental labs, we empower owners with advanced education for digital workflow, change management consulting and digital impression taking devices for increased productivity and revenue.

Contact us

3Shape Trios Scanner, Itero Intraoral Scanner

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

Check out the New EnvisionTEC 3D Printers! Just $45K from Kastle Mills

As a global leader in 3D printing, EnvisionTEC http://www.envisiontec.com/ manufactures top quality high resolution dental printing systems for your rapid prototyping and rapid manufacturing needs and a variety of materials to support your needs. See how a 3D printer from EnvisionTEC can help YOUR company succeed in growing your business. Call Kastle Mills Today!

Kastlemills is EnvisionTEC’s Authorized Canadian Distributor – Plug and Go with your 3Shape D700 or D800 dental scanner. Kastle Mills is your 3D Printing Centre for Dentistry

Dental Video from SSK Labs (Okay minus the German) It’s that easy! If you need a translator Sabina can help you English to German!!!!

3D printed partials, 3D printed wax patterns www.kastlemills.com Printers start at $45K

EnvisionTEC‘s new HTM140IV material is a great addition to dental model manufacturing. The ivory color provides an attractive choice for modeling similar to the standard gypsum color. It can be for dental training or patient education. It also shows fit markings clearly when used in the lab for the accurate planning of wax dental copings. HTM140IV‘s matte finish allows models to be laser scanned accurately for verification purposes. The high viscosity of the formula produces superior details and surface finish. HTM140IV is also tough enough for a dental technician to repeatedly remove and place the die at least 20 times without any loss of fit or causing any wear on the contact surfaces. The biggest advantage is its build time – a staggering one inch in under 90 minutes at 35 micron resolution in Z. .

Contact us

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

Kastlemills is EnvisionTEC’s Authorized Canadian Distributor – Plug and Go with your 3Shape D700 or D800 dental scanner. Kastle Mills is your 3D Printing Centre for Dentistry

Dental Video from SSK Labs (Okay minus the German) It’s that easy! If you need a translator Sabina can help you English to German!!!!

3D printed partials, 3D printed wax patterns www.kastlemills.com Printers start at $45K

EnvisionTEC‘s new HTM140IV material is a great addition to dental model manufacturing. The ivory color provides an attractive choice for modeling similar to the standard gypsum color. It can be for dental training or patient education. It also shows fit markings clearly when used in the lab for the accurate planning of wax dental copings. HTM140IV‘s matte finish allows models to be laser scanned accurately for verification purposes. The high viscosity of the formula produces superior details and surface finish. HTM140IV is also tough enough for a dental technician to repeatedly remove and place the die at least 20 times without any loss of fit or causing any wear on the contact surfaces. The biggest advantage is its build time – a staggering one inch in under 90 minutes at 35 micron resolution in Z. .

Contact us

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

Ankylos custom abutment solutions now available from Kastle Mills

ANKYLOS- Only from Kastle Mills can you access our Dental KLOUD ™ communication tools to approve your new patient specific abutment by way of vitual design approval – just click the video and approve our post your comments. Get the right abutment everytime! Kastle Mills is the new Canadian Beta Scanning Site (West) for 3Shape dental scanners.

ATLANTIS™ abutments are designed and fabricated using ATLANTIS VAD™ (Virtual Abutment Design) software, a patented process that combines state-of-the-art 3D optical scanning, advanced software and manufacturing methods to deliver patient-specific abutments that eliminates the need for hand modification. ATLANTIS™

Do you have a case and need a patient specific abutment with a lifetime warranty? Contact us for a solution for your centre!

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill

3shape 3D printing

Your 3shape Trios and dental scanning centre

www.3shape.com

www.3shapedental.com

3Shape Dental Scanner

3Shape D700 Impression Scanner. 3ShapeD700-scanner. The foundation for digital quality and productivity

Please See our new Hhot News Section at our Website support.3shape.com

www.kastlemills.com

ATLANTIS™ abutments are designed and fabricated using ATLANTIS VAD™ (Virtual Abutment Design) software, a patented process that combines state-of-the-art 3D optical scanning, advanced software and manufacturing methods to deliver patient-specific abutments that eliminates the need for hand modification. ATLANTIS™

Do you have a case and need a patient specific abutment with a lifetime warranty? Contact us for a solution for your centre!

3Shape D700 Sales and Service

3shape Ortho

3Shape D800 Sales and Service

3shape roland DWX-50 Mill

3shape roland dwx50 mill